|

Intralogistics systemsAsiaNewsPress CenterReferencesNews

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Sustainable room modules for social housing in France's metropolitan cities

|

Intralogistics systemsSouth AmericaNewsPress CenterReferencesNews

Paint shop for agricultural machinery from JACTO

|

NewsPress CenterNews

Steffen Schmitt new Vice President for precast concrete plants at system specialist Vollert

|

Intralogistics systemsNorth AmericaNewsPress CenterReferencesNews

Automated intralogistics for Logan Aluminum

|

Retrofit projectsEuropeNewsPress CenterReferencesNews

A good plan: Modular retrofit for increased production

|

Shunting systemsEuropeNewsPress CenterReferencesNews

Emission-free loading of hollow-core slabs with road-rail vehicle

|

Shunting systemsAsiaNewsPress CenterReferencesNews

Rapid train loading in the Bogatyr open-cast mine

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Automated train loading at ŠKODA with Vollert train handlers

|

NewsPress CenterNews

SEW-Eurodrive delivering two millionth DRN motor in Germany to Vollert

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Painting in breath-taking heights

|

NewsPress CenterNews

Vollert India is expanding production capacities for Asia’s building industry

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Bernegger Group once again acting as a pioneer with Austria’s first energy-neutral precast concrete factory

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Kitchen countertops just-in-time

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Economically producing aesthetic L-bricks

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

UNGLEHRT automates precast concrete production

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Soriba manufactures concrete stairs - optimized in terms of time, cost and CO2

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Automated from coil to fully recyclable aluminum packaging

|

Shunting systemsEuropeNewsPress CenterReferencesNews

Road-Rail Robot VLEX at Fret SNCF in the French Alps

|

NewsPress CenterNews

New construction systems and CO2-optimized plant concepts at the bauma 2022

|

Shunting systemsEuropeNewsPress CenterReferencesNews

Scrap Transport with Smart Road-Rail Solution

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Grupo Avintia industrializes at high speed Spain's construction sector

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

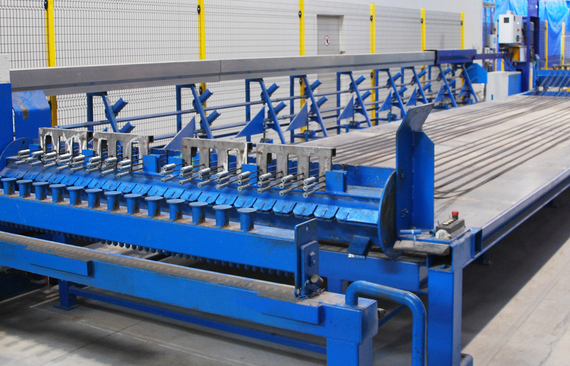

Planchers Fabre expands beam production

|

NewsPress CenterNews

From one cast: Tough Cast technology ensures long lifetime cycles with concrete spreader components

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

Russian DNS Development creates new living space at the gateway to the Pacific Ocean

|

Intralogistics systemsAsiaNewsPress CenterReferencesNews

Fast cantilever warehouse for sensitive foils

|

Concrete sleepersAsiaNewsPress CenterReferencesNews

Baku Metropolitan opens major metro station in the heart of Baku

|

NewsPress CenterNews

In the frame: Blue high heel shoe and the castle ruin „Weibertreu“

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Easy ballast coating at Liebherr

|

Intralogistics systemsRetrofit projectsServicesEuropeNewsPress CenterReferencesNews

Intralogistics made fit - without production downtime

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

A success story in Central Asia: Bolashak-T changes Kazakhstan's construction industry as a hidden champion

|

Shunting systemsSouth AmericaNewsPress CenterReferencesNews

State-of-the-art shunting technology speeds up soybean and corn handling at ADM do Brasil

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

True evolution: A novel construction system with reinforced-concrete hollow-core slabs is changing the cities of Central Asia by adding modern architecture

|

Press CenterNewsNews

Generous Donation of the Employees of Vollert Anlagenbau GmbH to the Clinical Center of Weissenhof in Weinsberg

|

Precast concrete productionAsiaReferencesPress CenterNewsNews

Thai DSC Product expands and invests in modern solid wall production

|

Precast concrete productionNewsPress CenterReferencesNews

MyHome Group produces semi-finished precast concrete elements for the Chinese construction boom in Jingzhou

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Kerkstoel 2000+ produces architectural precast concrete elements for high demands

|

Shunting systemsEuropePress CenterNewsReferencesNews

Road-rail Robot VLEX now up to 600 t tensile load

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

Indian Starworth Group focuses on exclusive living in the heart of Bangalore

|

NewsPress CenterNews

Cooperation with the Technical University of Kenya: African students learn about modern building systems with precast concrete elements

|

Precast concrete productionAsiaNewsReferencesPress CenterNews

Gamuda IBS revolutionizes Malaysia's construction industry

|

NewsPress CenterNews

New management structure: Vollert positions itself for the future with a new management team

|

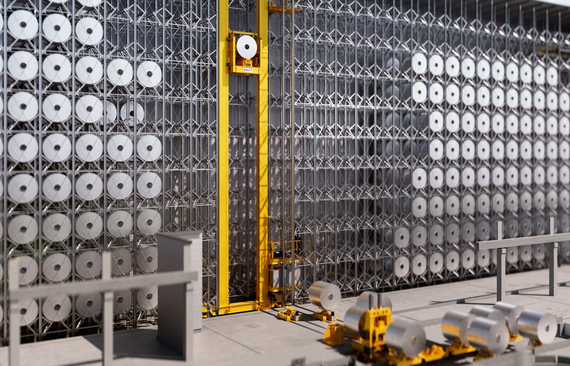

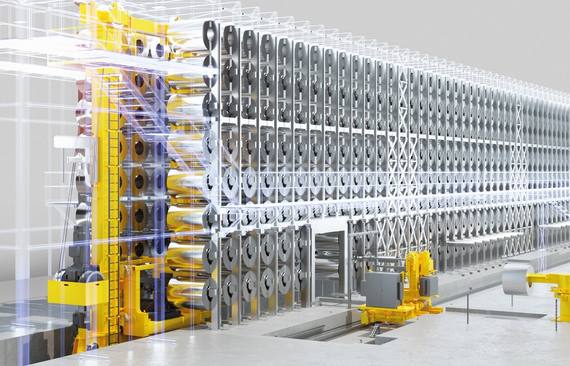

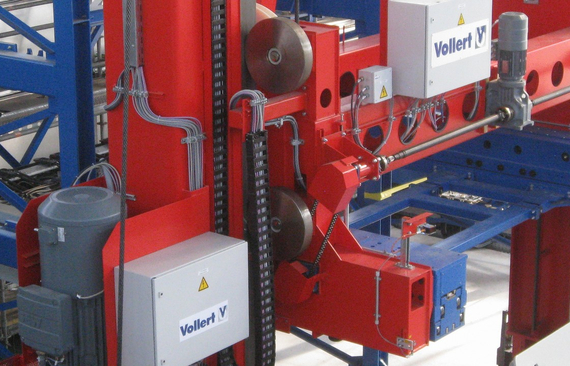

Intralogistics systemsEuropePress CenterReferencesNewsNews

Fully automated cantilever warehouse for steel coils

|

Intralogistics systemsRetrofit projectsEuropeNewsPress CenterReferencesNews

Vollert brings paint shop from Arburg to a high gloss

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Automatic, fully hydraulic, efficient: Hungarian Limelog Group expands stationary production of precast concrete parts

|

Shunting systemsEuropeNewsPress CenterReferencesNews

Environmentally friendly coal loading at the new terminal in Riga

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Fourth sheet metal blanks high-bay warehouse for automobile production

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Just-in-time precast floor slabs for the Belgian housing industry

|

Shunting systemsEuropeNewsPress CenterReferencesNews

Loading gravel fully automatically and environmentally friendly

|

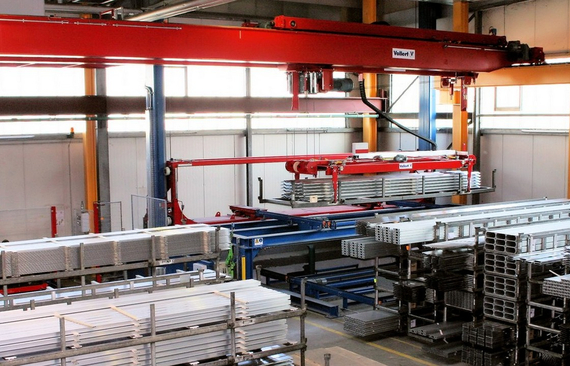

Intralogistics systemsEuropeReferencesPress CenterNewsNews

Aluminium profiles for e-mobility in highest quality

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Modular bathrooms efficiently and variable produced

|

NewsPress CenterNews

Earthquake-resistant and made to measure: New method for producing prestressed hollow-core slabs shown for the first time at bauma 2019

|

Precast concrete productionAsiaPress CenterReferencesNewsNews

Uzbek DSK Binokor develops earthquake-proof construction system for more living space

|

Intralogistics systemsEuropePress CenterReferencesNewsNews

Please blast, dip, powder a 100 times

|

Precast concrete productionEuropePress CenterReferencesNewsNews

The Oschatz concrete plant relies on robot technology

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Hot furnaces, cool mechanical handling

|

Shunting systemsEuropeNewsPress CenterReferencesNews

Tip and go: Loading by the cargo specialist Innofreight with shunting technology from Vollert

|

Precast concrete productionEuropePress CenterReferencesNewsNews

Industrial pre-production of TERIVA floor beams and slabs in Poland

|

Intralogistics systemsSouth AmericaNewsPress CenterReferencesNews

Weld, paint and fit wagons and trailers in one line

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

High speed production buffer for 3,000 tons of steel wire coils

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

Chinese Baoye Group continues to invest in precast concrete production

|

Intralogistics systemsRetrofit projectsEuropeNewsPress CenterReferencesNews

Fast cranes for heavy loads

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Large-part painting systems designed around the corner

|

Precast concrete productionSouth AmericaNewsPress CenterReferencesNews

Brazilian MARNA Pré-fabricados modernises stair production

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

bétons feidt creates special architecture in concrete

|

Shunting systemsEuropeNewsPress CenterReferencesNews

Compact with a smart steering

|

Retrofit projectsNewsPress CenterReferencesNews

Moving multi-ton weights fluidly

|

Concrete sleepersAsiaNewsPress CenterReferencesNews

Thailand uses railway sleepers made of steel reinforced concrete for large-scale railway projects

|

Retrofit projectsEuropeNewsPress CenterReferencesNews

Manufacturers of precast concrete elements increase product quality and system productivity through modernization investments

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

A breath of fresh air for anode production

|

Concrete sleepersAsiaNewsPress CenterReferencesNews

New type of concrete sleeper for Baku's Metro lines

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

Earthquake-proof construction systems on a precast basis significantly change the face of Uzbekistan

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

Highly-lively homes for todays Indian families

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

Shanghai Baoye relies on state-of-the-art precast construction technology

|

Precast concrete productionEuropeNewsPress CenterReferencesNews

Belgian Cordeel Group becomes a key player of the European construction industry

|

Precast concrete productionSouth AmericaNewsPress CenterReferencesNews

BauMax is developing a precast construction system for residential buildings in Chile

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Caution! Heavy load!

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

Twins usually come in pairs: Thai SCG Group invests in modern precast concrete production

|

Intralogistics systemsAsiaNewsPress CenterReferencesNews

Precise heavy-load crane systems for ingots and coils, etc.

|

Retrofit projectsEuropePress CenterReferencesNews

Vollert Exchanges twelve Stacker Cranes During Ongoing Automobile Production

|

Precast concrete productionSouth AmericaNewsPress CenterReferencesNews

Precast concrete elements for Brazil’s construction industry

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

From the 3D building model to the production-stage precast concrete element: know-how and plant technology for Kazakhstan’s building industry

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

New Caledonia focuses on precast construction

|

Concrete sleepersSouth AmericaNewsPress CenterReferencesNews

Prestressed concrete sleepers for the American continent

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

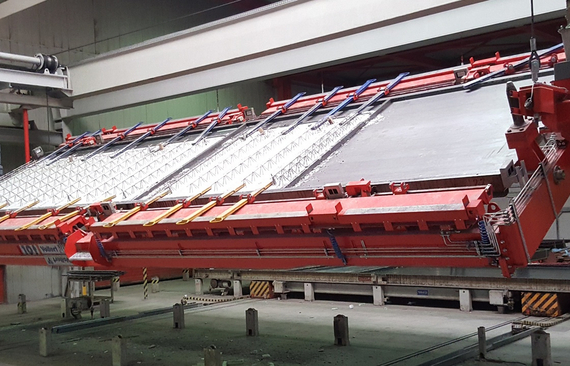

High-bay and automated intralogistics system speeds up production for Aleris

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Next stop: Paint center

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Up and away – Continental exchanges 75 meters of test track in a matter of minutes

|

Precast concrete productionAsiaNewsPress CenterReferencesNews

Precast concrete parts for the emerging India

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Fully automatic coil transport in Hydro aluminium mill

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

E-Mobility for Container Logistics

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Automatic long items and small parts storage for aluminum profile systems

|

Concrete sleepersAsiaNewsPress CenterReferencesNews

From 0 to 450.000 pre-stressed concrete sleepers: Inkol Insaat starts operating state-of-the-art production plant

|

Intralogistics systemsAsiaNewsPress CenterReferencesNews

Vollert manufactures transfer cars for coating 13,000 carriages annually

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

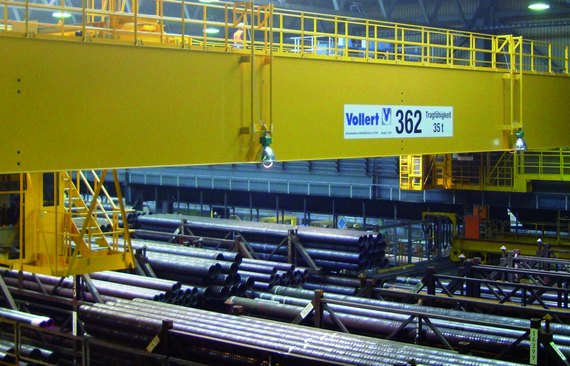

Vollert Anlagenbau develops a 260-ton automatic crane for Vallourec & Mannesmann Tubes

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Friction wheels transport large gearboxes for painting

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Yellow giants painted overhead

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Moving and Painting Large Items Efficiently

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Oven for construction machinery

|

Intralogistics systemsAsiaNewsPress CenterReferencesNews

Facility for loading 10,000 beverage crates per hour

|

Intralogistics systemsEuropePress CenterNewsReferencesNews

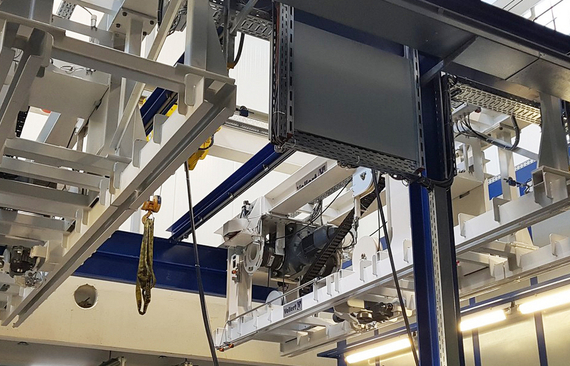

Custom manipulator with three synchronous hoisters lifts aluminium profiles up to 18 metres in length

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

50 tons of explosion-protected parts painted while suspended

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

SSAB stores up to 6000 tons of steel in a high-bay warehouse

|

Intralogistics systemsAsiaNewsPress CenterReferencesNews

Earthquake-resistant: New high-bay warehouse from Xiashun holds 800 aluminium coils

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

A dream car every minute

|

Intralogistics systemsEuropeNewsPress CenterReferencesNews

Caution, People Hard At Work!