The brain of the modern precast concrete plant

Today, a state-of-the-art production control system ensures an optimal and punctual supply of the required precast concrete elements to construction sites and customers. It continuously controls and monitors all processes and machines in the precast concrete plant, from work preparation and work stations to storage and loading processes. It is the central interface for the constructively created data from the BIM model and existing ERP systems. Consequently, it is also called the brain of a modern precast concrete plant. The Vollert Control Center incorporates all the usual CAD/CAM industry interfaces for this purpose.

Pallet allocation is optimized, all machines are controlled, data is automatically tracked and processed, retrieval sequences and curing times are managed and, of course, a large number of statistics are made available. This way you have all important order lists and key figures in view at all times. Printouts of label, element or allocation plans or their visualization at the workstation facilitate the production process and the subsequent storage location management. Here, the achievement of a simple operating concept has been taken into account in the development phase itself – simply “learning by doing”.

The functions at a glance

VCC DATA CHECK

Import of CAD data from the design department

CAD files of the concrete elements to be produced are automatically imported and checked for errors. Data that is incorrect is logged, the errors marked and displayed graphically. A 3D data viewer is included in the standard package. The CAM files for the machines and robots are prepared at the same time. Ready for IFC4precast.

VCC SLOT MASTER

Optimized work preparation

The concrete elements to be produced are pallet optimized, positioned, automated or manually, and order units formed. Batch specifications are taken into account. Parameter settings for automatic pallet assignment are possible.

VCC PRODUCTION CONTROL

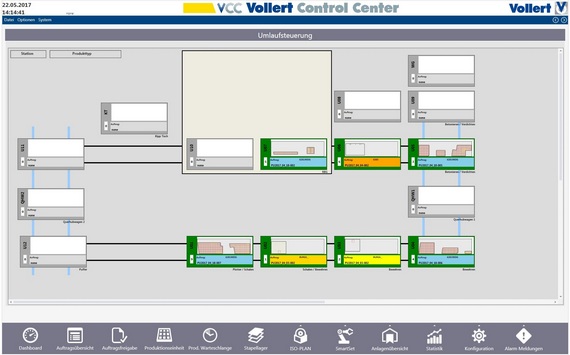

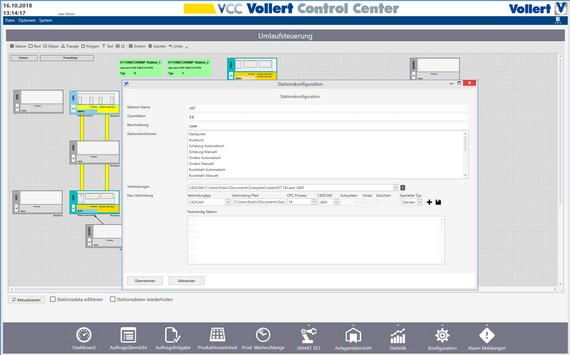

Circulation control and visualization

Visualization of all circulation positions with the associated production data as well as comprehensive fault reporting with time stamp for fault statistics and all relevant key figures. Current live display of the estimated production time for a concrete element (individual configuration is possible). Data exchange via OPC UA (future Industry 4.0 standard).

VCC PREDICTIVE ACTION

Quality control of CAD data

A check-up of the production data is carried out after the data is imported. For example, the lattice heights and the stiffness of the raised edges in double walls or the overlapping of the reinforcement in cutouts are checked. This enables production delays to be avoided in advance, ensuring high plant productivity and secure machine times.

VCC PRODUCTION MANAGER

Batch order processing and production control

Visual illustration of the order sequence of the production units in the pallet circulation system and the connected machines. Direct control of various subsystems, such as shuttering robots. It is also possible to make manual changes, such as reordering the production queue.

VCC STORAGE MANAGER

Storage management

Convenient and clear-view storage management of the concrete elements produced. The concrete elements are recorded, listed and booked out again via barcode scanners. Feedback to an ERP system can be made at any time. Parameters can be set for different retrieval strategies, e.g. the loading order, etc. A module for complex storage is available, as an optional extra.

Statistics and Data interfaces

VCC STATISTICS

Production statistics

Comprehensive evaluations with different filter settings over a defined time period. Consumption data for materials such as concrete, round steel, built-in parts, etc. can be evaluated and presented individually. A wide variety of key data such as the amount of concrete consumed per hour can be displayed graphically.

VCC REPORTS

Generating production documents

Creation of extensive accompanying documents (e.g. pallet or track layouts, CAD single sheets, labels for marking, commission or parts lists) for production. The format and structure can be customized. Reports can be displayed, for example, on the workplace screen or printed out in paper form.

VCC INTEGRATE

SMART SET shuttering robot

Optimized, automated positioning of the shuttering systems. Various options and strategies can be selected. Graphical representation in 2D and 3D is possible in real-time mode/simulation mode.

VCC MACHINE CONTROL

Machine and robot interfaces

The Vollert Control Center can cater for subsystems from different manufacturers. Individual interfaces can be implemented at any time. Providing subsystems, such as reinforcement machines, with CAM data can be carried out parallel to the production process or at different times.

Workflow and Highlights

The technology

The Vollert Control Center is designed as a multi-tiered, service-oriented application. The business logic and data access level are integrated into a web service running on a Windows-based operating system with .NET Framework 4.5 or higher. The VCC’s database is based on MS-SQ L Server (version 2012+). Both applications can be run as direct installations or on virtual machines. They can also be run locally or remotely and can even be cloud based (e.g. Azure) if required.

The web service-oriented architecture enables the implementation of different user

interfaces. The VCC’s main application is a WPF (Windows Presentation Foundation) application. This application requires a Windows operating system with .NET Framework 4.5 or higher.

Data interfaces

Data exchange formats with CAD systems:

• Unitechnik (v4.0-7.0/UXML)

• PXML

• IFC4precast

• More on request

Data exc hange formats with machines and subsystems:

• Unitechnik (v4.0-7.0/UXML)

• Unitechnik-Imagefile (Version 1.0, 2.x)

• Unitechnik Report-File

• BVBS 2.0

• More on request

Data exchange formats with ERP systems:

• Database-Based ER P system-proprietary communication protocols

• File-based ER P system-proprietary communication protocols (text files, XML files, CSV files, etc.)

Database interface for di rect database queries from external systems:

• SQ L Server view-tables that can be queried externally

• The view-tables form a documented interface based on PXML

• Direct data queries via external systems