GIC Ingeneria y Construcción has been one of the leading building contractors in North America for over 30 years. Precast concrete elements such as hollow decks, wall elements, columns and beams for residential and industrial construction as well as concrete girders for bridge and road construction can now be found in over 700 building projects. For further growth the GIC group invested in a new precast plant for prestressed concrete sleepers in 2013. "A sustainable plant concept, flexible processes for an increase in capacity later on and high safety at work were important to GIC in the design of the mould circulation plant. That's what we focused on", says Steffen Schmitt, Senior Sales Manager at Vollert.

Increase to 350,000 prestressed concrete sleepers annually in several development stages

Thanks to its compact plant structure, the pallet circulating plant has a footprint of 1,200 sq. metres. In several stages of development, a maximum annual production capacity of 350,000 prestressed concrete sleepers is to be achieved. In 2-shift operation that is equivalent to a daily output of over 1,300 concrete sleepers. 280 sleeper moulds are in constant circulation for this.

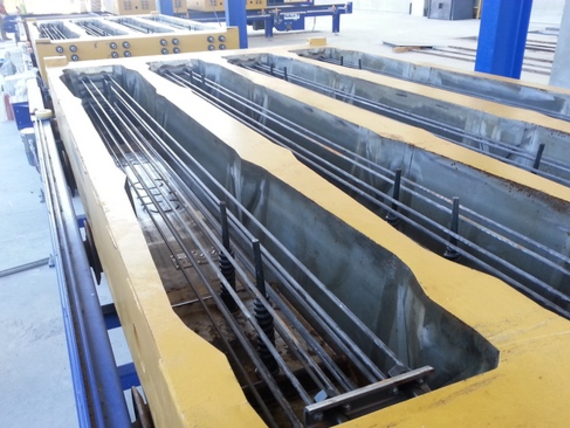

Production of the prestressed concrete sleepers began in March 2014. The quadruple sleeper moulds are oiled and cleaned first before the installation of the anchors for the fastening of the rails later on. Subsequently, the prestressing wires are installed in the mould prior to concreting. With the aid of a button heading machine, four individual wires are connected with two anchor plates to make an assembly before the anchor plates are fastened to the tensioning and anchor bolts in the sleeper mould. Subsequently, the wires are prestressed by means of the tensioning bolts whilst constantly monitoring and recording the tightening torque of each prestressing wire. In order to ensure high safety at work, pressure-sensitive mats are installed in this work area. As soon as a worker steps on the pressure-sensitive mats the prestressing procedure is interrupted and the transport of material is stopped.

The preassembled mould is transported onwards by roller conveyors to the soundinsulated concreting chamber. The semiautomated concrete distributor fills the moulds precisely via electrically driven discharge screws. A high frequency vibrating station ensures homogeneous concrete compaction. Floor space for a further compaction station has already been earmarked in this work area for an extension in capacity later on. The concreted mould is subsequently transported via a corner transfer conveyor and chain conveyors to the hardening chamber. There, an overhead crane takes up the quadruple mould by means of a suspended spreader bar and stacks up to eight moulds on a prepared trolley car. The hardening chamber is thermally insulated and equipped with a heating device. The trolley cars move through the hardening chamber on rails according to predefined cycle times. To this end a chain pusher pushes the entire train of cars one car length further at a time. In the exit area a further chain pusher pulls one run-off carriage at a time out of the hardening chamber following a hardening time of about 20 hours. A total of three transport for the transport and for the turning of the mould", explains Steffen Schmitt. First of all the moulds are taken off the run-off carriage and stacked on a chain conveyor. The prestress release process is subsequently initiated via a semi-automated detensioning station. To do this the prestress is introduced into the concrete sleeper.

Subsequently, the turning spreader bar turns the mould by 180 degrees, before the shake-out process is carried out by means of an electric lifting mechanism. After shaking out, the mould is turned back by 180° and fed back to the mould circulation. The manufactured prestressed concrete sleepers are delivered ready for laying. For this the entire reinforcement is installed in the sleeper and prestressed according to the standards. The rail fastening is also ready installed. The demoulded sleepers are transferred to the rail support assembly for this.

High plant productivity and safety at work

"Vollert was the right know-how partner for GIC for both the engineering and the plant technology. We have found the correct balance between the degree of automation and high plant productivity. In further stages of development we can easily adapt our new precast plant to the output quantities that we are aiming for", says Mauricio Gutiérrez, Sales Director at GIC. "At the same time, particular attention has been paid to safety at work in every work procedure."

With this investment GIC has taken a further important step into the future. It is now aiming not only at the Mexican sales market, but also at international markets and in particular the US market.