SMART SMOOTH Trowelling machine

The surface of the precast concrete part facing away from the casing is smoothed by the trowelling machine. The precast concrete part is stored for a specific period of time in the curing chamber or else in a buffer at trowelling stations. The trowelling machine then travels over the pallet and smoothes down the concrete part. The trowelling machine is equipped with adjustable rotating vanes and various add-on discs.

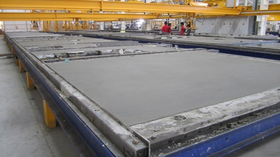

Puller

The surface of the precast concrete part facing away from the casing is smoothed directly after the concreting by the puller. This is done by installing the puller board as a separate machine or on the concrete distributor, pulled over the surface of the concrete in the lengthways direction of the pallet.

Blast system

Once the concrete part has hardened, it is transported to the blast system. This is done, for example, on a transfer carriage or with ceiling-mounted conveying systems. The degree of automation depends on what the customer wants. The surface of the concrete part is then blasted by an operator in the blast system until the desired effect is achieved.