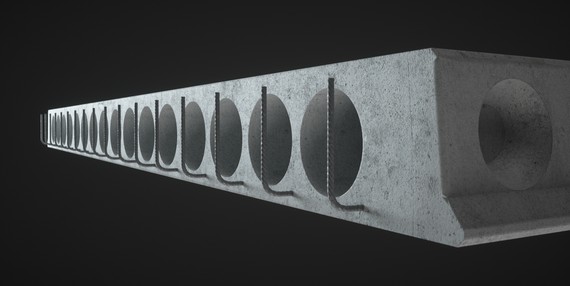

Hollow-core slab

With hollow-core slabs, special interior spaces are left out, which significantly reduce the dead weight. This makes them unsurpassed economical when it comes to transport and installation over large areas on the construction site. In addition, hollow-core slabs can be combined with almost all types of walls and floor slabs and supplied today as reinforced or pre-stressed execution. Further advantages are the low construction heights with high surcharges and a very good, largely pore-free view from below.

Standard hollow-core slab

Non-prestressed hollow-core slabs, also called DX slabs, are produced commercially as standard hollow core slabs of 20 and 24 cm in thickness. The reinforcement that is required for structural reasons has already been built into the concrete part by the manufacturer. Due to the reduction in weight of up to 40% as opposed to a solid floor, there are savings in materials in manufacture.

A hollow core slab can be laid without any supports, and no concrete topping is required on site. For that reason, there is no dampness arising from the construction work. Quick installation is possible, the construction time is reduced and the costs can be cut. The smooth and flat lower layer is ready for wallpapering after the joints have been grouted. Mix-in-situ concrete is only necessary for the ring anchors.

MOTUS hollow-core slab

Hollow-core slabs are up to 40% lighter than solid slabs and require less concrete to manufacture. The hollow-core slab is usually laid without support and can be fully loaded immediately. Grout topping on site is no longer absolutely necessary. For these reasons, it is widely used worldwide.

Previous disadvantages

In the traditional production system, comprising a continuous casting process on long production beds, transverse reinforcements, cross connectors, built-in parts, lifting rings, tensioning steel overhang or concrete recesses cannot be incorporated at all or can only be incorporated with considerable expenditure. Because of this, prestressed hollowcore slabs are often not permitted for construction systems in earthquake zones, or can only be used with restrictions. Also not to be underestimated are the previous scrap costs due to scrap sections produced in the cutting process.

Hollow-core slabs in a circuit

Vollert's innovative solution takes completely different approach in order to rid the undoubted advantages of the prestressed hollow-core slab from the disadvantages it incurs from its traditional manufacturing process. For the first time, prestressed hollow core slabs are produced on pallets in a circulation system. In this system, each hollow-core slab is produced waste-free to the precise geometry and dimensions of the desired building component.

Tensioning and additional reinforcements, cross connectors, coupling elements, built-in components and recessed placeholders are easily installed on the pallet. Hollow-core creators are only used temporarily during the concreting process. Truly earthquakeresistant prestressed hollow-core slabs can now be produced for the first time.