Automated intralogistics for Logan Aluminum

Intelligent material flow systems ensure smooth interfaces and fast, reliable transport and storage processes between the machining and processing steps in aluminum production. This requires a great deal of know-how to design the process chain productively and also to create the ideal software architecture.

The expertise we have built up over more than 40 years of customer projects worldwide. Numerous well-known customers from the aluminum industry rely on our proven intralogistics concepts for the economical production of high-quality foil, sheet or extrusion profiles for the automotive, aerospace or medical industries.

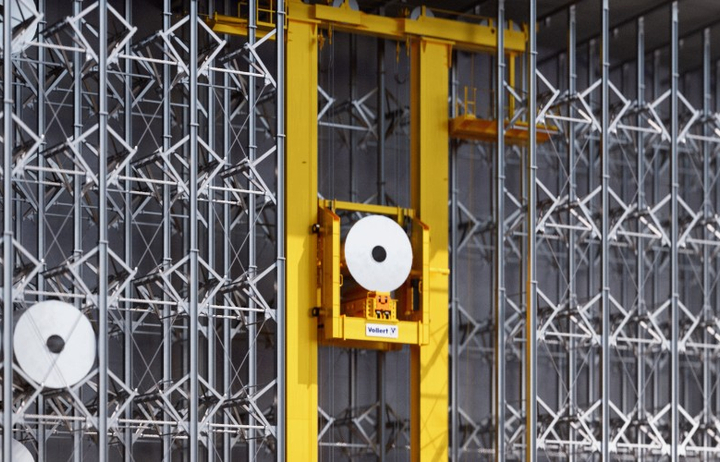

For the cost-effective production of high-quality aluminium products such as foils, strips or sheets, the optimum integration of the various production processes in rolling plants is crucial. This requires fully automated intralogistics solutions to ensure resource-saving and efficient workflows. From automatic crane systems for the raw aluminium ingots and the logistical linkage of hot and cold rolling mills, through to intelligently designed transport and storage systems for aluminium coils weighing up to 35 tons and at temperatures of several hundred degrees, which are particularly susceptible to damage from the outside.

That we meet these requirements perfectly has already been successfully proved by Vollert in an impressive number of international projects:

Whether in the form of window frames, vehicle trim strips or football goal posts - we frequently come across aluminium profiles in everyday life. What they have in common is the production method: they are pressed as up to 50-metre long extruded profiles from aluminium billets, cut to transportable lengths of between six and eight metres and automatically stacked in transport skips. Depending on the desired end product, the profiles can be hardened in ageing ovens, refined by anodizing or powder-coating.

In order to avoid bottlenecks, the intralogistics systems from Vollert ensure smooth-running processes and perfect interlinking of the individual production stages:

In aluminium primary production, the requirements for storage and transport systems are particularly high. Additionally, the aspect of environmental protection and resource saving must be taken into account. We have precise knowledge of the environment and ensure durable and future-proof processes and transport systems.