made by Vollert

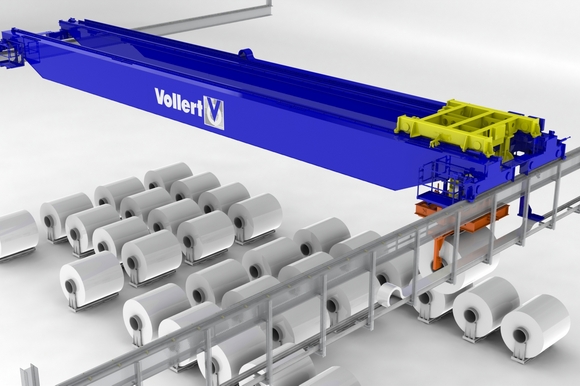

When transporting and storing heavy loads and large-scale parts, we have been incorporating the 3rd dimension for over 50 years with automatic crane systems and are shifting logistics processes upwards. Today, modern crane and lifting technology networks internal material flows with high transport speeds and numerous integrated Smart Features such as load positioning or optimized synchronization of travel and lifting axes.

There is no catch with us

Configurators? We don't know that. Whether bridge crane or semi-portal systems, we develop the customized crane system from a proven modular system in dialog with our customers. We do not rely on standard solutions, but always adapt the crane and lifting technology to the customer's needs. This applies in particular to the load handling attachments, where we use lifting grippers, tongs and traverses that are precisely tailored to the workpiece instead of conventional load hooks.

Automatic heavy duty cranes from 2 tons

Heavy-duty cranes from 2 tons in automatic or semi-automatic operation - that is our strength. Even demanding environmental conditions such as in paint shops, explosion-proof areas or in aluminum and steel production are no problem for our plant technology. Even the transport of 1,300 °C hot steel or oversized components is possible. We know no limits with regard to the industry. Wherever heavy materials and huge parts have to be transported reliably, we will find solutions for your logistics tasks.

For more than 50 years, crane systems with Vollert's technology and know-how have been world leaders. Each crane system is individually planned and built. With our great expertise, we know and understand the special, industry-specific requirements.

Process cranes network and integrate all material, machining and processing operations - whether in the aluminium and steel industry, in automobile production, energy and recycling or in paint shops.

The path to networked intralogistics with digitalization and automation

For economically efficient production, automation of internal material flows is indispensable. At the same time, the increasingly important interaction between human and machine must be strengthened. Rigid storage and transport processes turn into flexible value-added chains. Data and relevant information are digitally recorded and assessed in real time. Logistics processes are linked to each other in a path-, flow- and time-optimized manner.

State-of-the-art visualization software and digital twins let us simulate later intralogistics processes in advance, in order to develop the best solutions. Virtual commissioning is also possible now.