VArio TURN Pallet-turning equipment

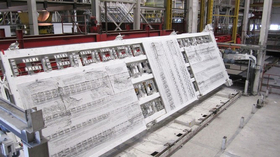

When producing double walls, it is necessary to rotate the hardened upper part by 180°, position it over the freshly concreted lower part and then lower it.

One way of doing this is to use pallet-turning equipment, in which the pallet with the upper part is transported by means of a special crossbeam during the turning process. The complete casing pallet with the upper part is locked in place and rotated. A patented tensioning-arm system ensures that this operation is simple and uncomplicated.

Depending on the requirements of the plant in question, either stationary or ceiling-based pallet-turning equipment can be used.

VArio VAC TURN Vacuum-turning equipment

Turning equipment is required for the manufacture of double walls. One possible method is in the form of vacuum-turning equipment. This makes it possible to reduce the gap between the two wall sections to almost zero, resulting in a wall with two smooth sides.

To do this, the first part of a double wall, once it has been completely cured and hardened, is moved by lifting equipment from the casing pallet and positioned on the vacuum shells of the turning equipment. The first part is fixed to the turning frame by applying an underpressure. Then it can be rotated by 180° and positioned in the freshly concreted second part. When the vacuum is deactivated, the first part is released from the turning frame.

As a matter of course with Vollert: a carefully welded construction that is vacuum-tight and many automatic functions when generating and monitoring the vacuum make this modern technology a production method that is widely used today.