column moulds

Hydraulic column moulds provide maximum flexibility, because they are available in any length required. As standard, heights of 400 - 1,200 mm and widths of 100 - 1,000 mm are possible, optional height and width extensions can be realised at any time. Whether as a mono or duplex mould - configuration is possible in almost all dimensions to suit your specific requirements.

In this case, the column mould consists basically of a formwork base with a fixed centre platform and movable side platforms. Sections of the mould with different lengths can be operated individually or hydraulically by means of coupling plates across the entire length. Using an optional sliding plate, which is connected to the side platform by means of a pulling mechanism, demoulding is made considerably easier. In this case, the finished conrete element together with the floor mould rests on the sliding plate and is separated from the centre mould surface before lifting out.

Column moulds are also available with an additional mould unit for the production of the foundation footings. A pre-stressing unit can also be integrated for the production of pre-stressed concrete elements as well as a heating register. To compact the concrete, vibrators are attached to the steel side formworks or side frame grids. In the KOMBITEC design, a variable installation at the required positions is also possible. In this, the vibrator motors transfer the energy to the mould via a central tube.

Choose between mono moulds or multi-functional duplex moulds for maximum plant productivity. In this, the side frames are available as mould grates for on-site ply-wood covering or with steel covering.

The construction in the context of bottom formwork, side panels and wall panels is designed so that a variety of concrete elements can be produced on an exceptionally cost effective basis:

The universally mould panel system is length and height compatible. In this context the KOMBITEC elements are exceptionally variable in the longitudinal and height grid. A configuration to create a cross console in different heights is possible, as well as frame constructions.

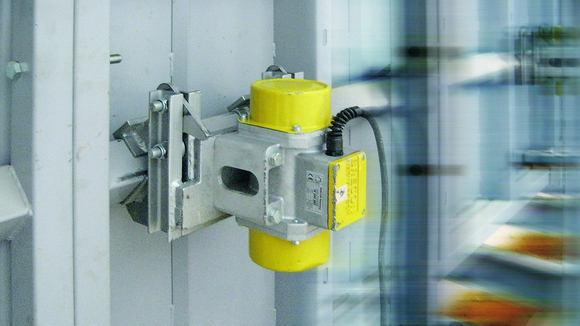

The couplings are designed to align the panels area-equal with quick release mechanisms. The integrated central tube guarantees the rapid coupling and the independent positio-ning of the vibrators. This construction ensures the optimum compaction of the finished element.