Automatic, fully hydraulic, efficient: Hungarian Limelog Group expands stationary production of precast concrete parts

High-performance tilting tables allow the flexible, horizontal manufacture of wall and façade elements and laminary special parts. Hydraulic tilting joints, fixed with the tilting frame and tilting block, set up the mould surface up to a tilting angle of 83° and ensure stripping without concrete edge failure. First class exposed concrete surfaces are guaranteed by the plane-ground mould surface.

Whether as version with fixed side rail, with height adjustable side rail in the range of 120 – 350 mm or as wooden construction mould with height adjustable substructure – the construction is designed so flexibly that any number of wall heights can be manufactured.

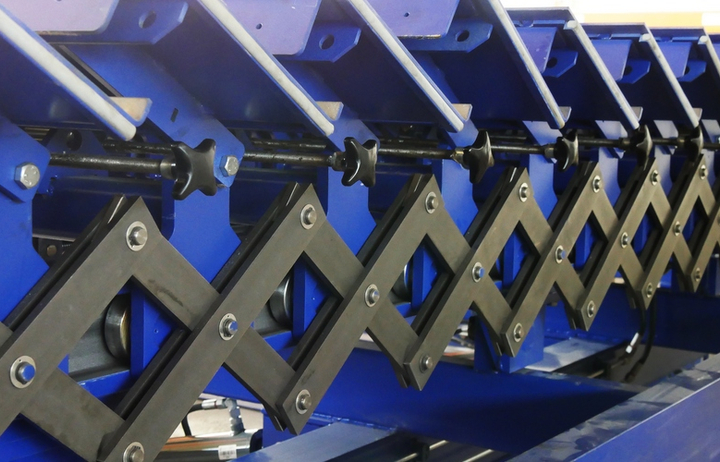

An extremely solid welding construction made of steel profiles means positioning on even ground without foundations is possible. Torsion stiffness guarantees construction of lare dimensions. All current shuttering systems can be used.

There is a selection of various concrete spreading systems for casting the concrete, whether crane-driven, as a bridge or portal concrete distribution systems. We also provide solutions for surface treatment from simple screeding to surface finishing systems. Also the combination of a tilting formwork table with a separately drivable mobile tilting unit and a mobile drivable plotter is possible. Special high frequency vibrators compact the concrete to make it homogeneously.

The construction is designed so flexibly that numerous solid elements can be produced extremely economically:

To produce particularly large casting areas for up to 100 m in length, tandem tilting tables are used. To do this, a mould bridge is fitted between the tilting tables and connected to the hydraulic system.

In this way, several tilting tables can optionally be synchronised with each other. However, the individually combined tilting tables can also be used individually at any time.