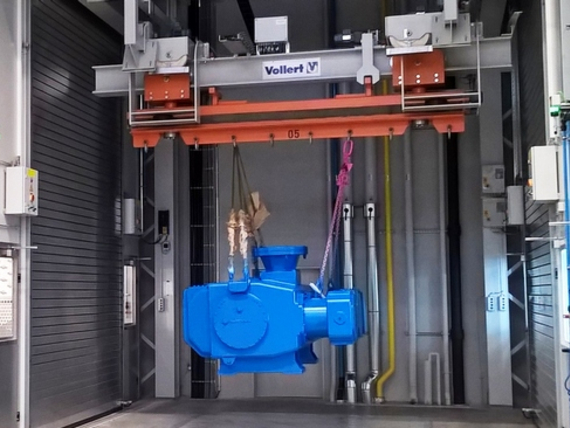

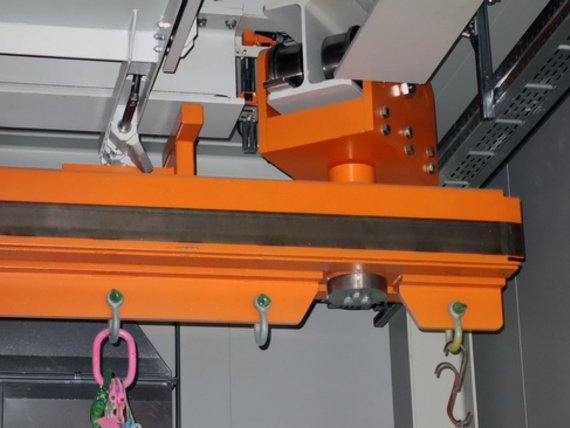

On the one hand, at LEWA in Leonberg, special pumps weighing up to 12 metric tons were supposed to be cycled in the drying process one after another as with a circular chain conveyor; on the other hand, however, the coating system needed to be constructed in an especially compact and space-saving way. Because such tight radii are not possible with a circular conveyor, the engineers at Vollert developed a new type of solution with turning elements on the ceiling-guided rails and on the chassis of the friction-geared product carriers.

Guide rails run straight around the corner

The system from Vollert does not follow a larger radius or a curved path; rather, the product carriers with the workpieces are brought directly "around the corner" by 90° and in a maximal space-saving way. For this purpose, the guide rails within the dryer are split at two places - the layout of the chassis of the product carriers makes it possible to bridge the gap without problems. After the arrival in the 15m-long dryer, the two parts of the guide rails turn 90°, while the product carrier, thanks to the rotatable suspension bracket, maintains its position. After that, the product carrier travels transversely to the side, cycled together through the dryer. At the end, conversely, pivoting guide rails enable the piece to exit longitudinally to the post-processing and to the loading and unloading manipulator. "All workstations have a place in an area of only 15 x 25 m: loading and unloading manipulator, wash cabin, coating cabin, dryer and post-processing," explains Jochen Keinath, project manager from Vollert. It is thus possible to cycle up to seven product carriers with a total load of 84 tons simultaneously in the tightest space.

Road rollers in a 10-minute cycle

At HAMM in Tirschenreuth, the bar was equally high. Thanks to a sophisticated logistics concept, the roller manufacturer has the most modern roller factory in Europe. The requirements for the new coating are correspondingly ambitious: Every 10 minutes, a roller drum leaves the system - with a weight of up to 10 metric tons.

The roller drums are painted complete with the mounted drive and oscillation technology. Because only the sides are painted, the developers from Vollert were able to rely on floor conveyor technology this time. Two distribution trolleys, arranged centrally to the work cabins, automatically transport the roller drums, which are stored on skids, to the free workstations, slide them off and pick up the finished ones. The trick thereby lies in the optimal interaction, which was calculated by Vollert in advance through a simulation: While one of the distributor trolleys exclusively serves the preparation and wash cabin area on a short stretch, the second is designed as a long-distance runner in a double version. Thus, on each trip, it can bring in one roller drum and carry out one roller drum, with a short drive in between.