Vladivostok is one of the most important Pacific ports in Russia, with a population of more than 600,000. The main economic sectors are the port and fishing industry as well as the naval base. Vladivostok is also economically important due to its proximity to the borders of the People's Republic of China and Japan. However, many young people are turning their backs on the Primorye region due to a lack of economic prospects. They are drawn to Russia's mega-cities such as Moscow, St. Petersburg or Novosibirsk. In order to strengthen the region, state subsidies and funding programs are being used.

At the same time, attempts are being made to gear urban development to the changing expectations of Generation XYZ. Special housing programs for young families are required. Issues such as climate change and sustainable construction, smart homes with a high quality of living and modern architecture must be compatible with the creation of affordable housing for as many people as possible. The digitalisation of the construction process is a crucial factor here, as is the highly automated, factory-based pre-production of all components and parts such as walls and slabs. "In order to handle more than 75% of the construction processes in an industrialized manner and independently of the construction site, a general change in mindset is required," describes Igor Chukov, Executive Sales Director CIS and Eastern Europe at the plant engineering specialist Vollert. This requires new construction systems and forward-looking representatives in politics and the construction industry who are taking bold and innovative steps forward here.

DNS-Development implements mega housing projects in Russia's Far East

DNS-Development Group has been one of the leading construction companies in the Primorje region since 2012. More than 200,000 sqm of construction space have already been realized. This also includes large infrastructure projects and logistics properties. "Residential projects are another important pillar of our growth strategy", explains Pavel Leganov, General Director at the subsidiary DSK. "DNS City is certainly the largest residential project at the moment. It is a lighthouse project for a completely new urban architecture in Russia. More than 600,000 sqm of residential space will be built in the coastal city of Novyi, just 40 km from Vladivostok, over the next 5 years. On more than 100 hectares, a new "green" urban district is being created with plenty of feel-good guarantees for young families and singles. Construction work will start at the end of 2022. "While the planning phase for the major DNS City project will be completed by 2022, another residential project by DNS Development is already a reality. "In the x residential quarter Format in the Nadezhdinsky district, the first residents have already moved in" describes Pavel Leganov, visibly proud. 17,500 sqm of living space have already been newly created by DNS Development in its capacity as property developer. "And this is just the beginning. There will be a total of 15 two- to eight-storey residential complexes. An 8,600 sqm district shopping centre is also already under construction. Construction of a new school and kindergarten is scheduled to begin this year. All completely in prefabricated construction. “

DNS-Development's transformation from a pure construction developer and investor to a fully integrated property developer began very early on. "In order to cope with the growing construction projects in a short time, we have been manufacturing structural precast concrete parts such as prestressed columns, beams and stairs as well as hollow core slabs and solid walls ourselves in a modern precast concrete production facility in Nadezhdinskaya since the end of 2018" explains Pavel Leganov. Only about 30 minutes away from Vladivostok, the construction sites can be reached quickly and just-in-time. In mid-2020, the next milestone in the unique success story of DNS-Development was reached. Not only the construction system was expanded, but also the capacities in precast concrete production were adapted to the booming construction demand. Whereas production processes had previously been predominantly stationary and with little automation on tilting tables and a battery mould, the expansion was based on industrial, highly automated pre-production of the walls. "The pallet circulation principle has clearly proven itself in Europe and Asia. Several 100,000 sqm wall surface can thus be produced in a small space with little manpower, analogous to the automotive industry" explains Igor Chukov. Pavel Leganov, as a former manager in the automotive industry, contributes a lot of his know-how here. From the very beginning, the company relied on modern management methods and stringent Kaizen quality management.

Modern construction system with sandwich walls and architectural clinker brick facade

For the special architecture in its building projects, DNS-Development relies on sandwich walls with a curtain wall clinker facade. Efficient, slim solid concrete elements are used for the interior walls. We are currently planning to produce 100,000 sqm of wall surface annually in the future," explains Konstantin Martynow as the responsible production manager. For the new plant technology for the production of the precast concrete parts, DNS Development sought the know-how and expertise of an experienced concrete plant specialist. "The selection discussions for this were very intensive. It was important for us to be able to discuss controversial topics in order to optimally integrate the production-side processes into the DNS concept" says Konstantin Martynow. At the end of 2020, the decision was made in favour of the German plant expert Vollert. "Vollert convinced us, especially due to their expertise from numerous successful plant projects in various industries, not least in the automotive sector."

From the very beginning, the focus was on integrated work processes. "The residential building complexes are initially created virtually in 3D. All the important data for the walls and slabs to be produced flow directly into the production processes and into the pre-planning of the construction site processes on a CADCAM basis," explains Egor Kraus, the responsible project manager at DNS Development. However, the production control system used is also crucial for maximum plant productivity. The Vollert Control Center (VCC) is the central interface for the design data from the CAD data, the ERP system and the machine technology. Throughput times and automated pallet occupancies are permanently optimized, all machines are controlled, data is automatically tracked and processed, retrieval sequences and curing times are managed and a large number of statistics are made available. "It is therefore often referred to as the heart of the modern precast concrete plant" says Igor Chukov.

Intelligent production processes determine the plant concept

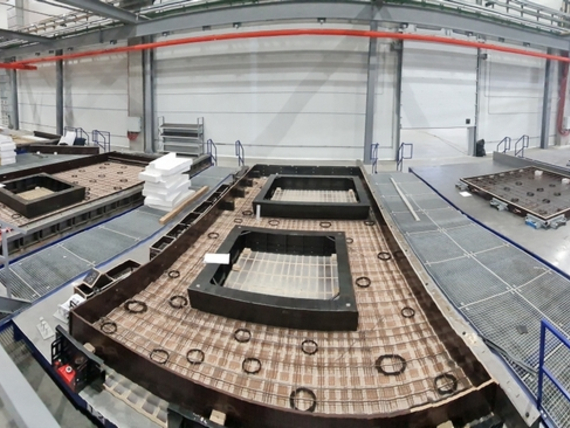

The production processes in particular were discussed very intensively as early as the preliminary planning stage. "Up to 40 transport pallets, which have fixed side rails, move between the individual work stations on a circulation basis," explains Daniel Krusche, the responsible project manager at Vollert. The insertion of the clinker elements for the outer facade is carried out by hand and is time-consuming. The transverse and longitudinal formwork profiles, the fixed frame boxes for the door and window recesses, as well as the reinforcement and insulation material are also positioned individually by hand, depending on the construction project and the degree of utilisation. "However, this means a longer dwell time for these manual preliminaries. To avoid waiting times, we work with parallel transport lines and discharge positions throughout the entire plant concept, partly separated by special safety barriers and fences" says Daniel Krusche. "With these net-like working islands, we are more flexible by a factor of 3 without reducing the plant productivity." Special handling traverses from Demag are used to transport the shuttering profiles and the reinforcement meshes between the individual lines and workplaces. Walkways enable safe movement between the individual workplaces.

"Furthermore, we work on several intermediate levels," Daniel Krusche continues. The surface finishing of the load-bearing sandwich wall face or of the solid wall is carried out on a working level directly above the concreting line. For this purpose, the VArio STORE storage and retrieval machine takes over the semi-finished wall elements and transports them through the top shelf of the curing chamber to the intermediate level. A VArio SMOOTH trowelling machine with variably adjustable rotational speeds travels in longitudinal and transverse direction and ensures formwork-smooth surfaces. Once the desired surface finish has been achieved, the wall element is returned to the curing chamber for further curing. This work step can also be carried out several times.

The right concrete mix and a controlled curing process are crucial

Another essential quality factor for the subsequent wall quality is the concreting process and the optimum concrete mix. "The decisive factor here is a concrete recipe that is individually adapted to the construction system and the climatic conditions" explains Dipl. Ing. Andreas Titze, who as a concrete technology expert supervises Vollert's plant projects. "Here it is a matter of topics such as temperatures, concrete stiffness, but also costs. " For the permanent optimization of the right concrete mix, a special laboratory has been set up with state-of-the-art technology. "The right concrete has an immense impact on profitability and wall quality. Therefore, we place great emphasis on this. So we not only supply the pan, but also the baking recipe, if you describe it figuratively" says Igor Chukov Vollert.

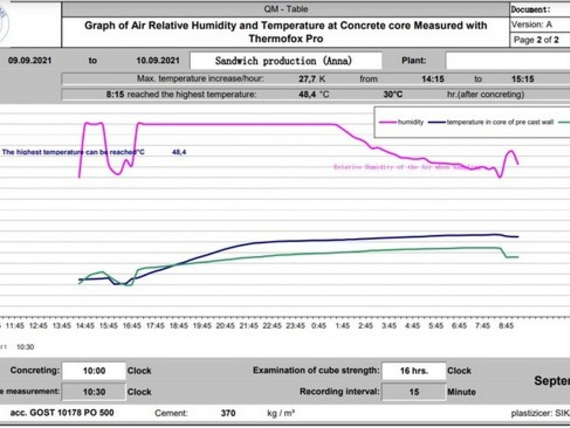

A real novelty of this plant project is the new speed curing solution that Vollert developed together with Andreas Titze and the customer. The decisive role here is attributed to the sub-process of controlled strength development in the core of the concrete element. A circulation and humidification system specially developed by Vollert for this purpose allows the concrete to harden under the optimum ambient conditions. The temperature development in the core is constantly monitored and recorded. "This process ensures the reduction of cement consumption, faster strength development and uniform heat increase" explains Igor Chukov. Extreme temperatures above 60°C are avoided. The quality of the concrete element meets not only the GOST standard, but also the highest expectations for the sustainability of the structure.

Two parallel concreting lines with SMART CAST automatic concrete spreaders ensure optimum concrete cycle times and precise concrete metering. The combination of feeder gate and spiked roller reduces under- or over-concreting of the desired discharge quantity, and this with process reliability and very high availability. In sandwich wall production, after the concrete of the facing layer has been applied, the insulation preparation and the insertion of further installation parts such as connecting and lifting anchors are carried out first. Then the top or load-bearing face of the sandwich wall is concreted. The concreting process is supplied by the specially designed bucket conveyor system. The planning specification of an online signal exchange between the concrete spreader and the bucket conveyor with variable transfer positions guarantees short travel distances of the concrete spreader and maximum available, effective concreting times. Compaction of the concrete by means of a combined VArio COMPACT2 shaking/vibration station ensures an optimum exposed face of the solid walls as well as compaction of the more reinforced load-bearing face of the sandwich walls. The low-frequency vibrating motion is generated by four unbalanced drives, thus compacting the concrete. The curing process is carried out in a fully lined and heated VArio CURE curing chamber with five opposing rack towers and 8 curing bays each.

For loading onto transport racks, the walls are erected by means of a VArio TILT tilting station. This is done at an angle of 80° so that the sandwich walls can be safely removed without breaking the edges of the facing layer. A hydraulically movable support beam moves against the fixed side rail, thus preventing the concrete element from slipping during the tilting process. For lifting and loading onto transport racks, the lifting anchor is first attached to the wall element by means of a mobile lifting cage, which ensures increased working safety compared to a conventional access ladder. "A SMART LOGISTICS run-off system was another very intelligent solution within the loading concept" says Daniel Krusche. Here, an extension carriage connects the loading area with the spacious outdoor storage areas. From there, the loading racks are distributed to the truck bays for transport to the next construction sites.

First construction sites already successfully supplied

Despite some very difficult conditions due to the Covid 19 pandemic, all installation work ran on schedule. "Not only in the new sandwich conversion line. Individual processes and machines were also modernised in the existing stationary line to increase plant productivity. For the wall production with stationary battery moulds, Vollert supplied a new semi-portal concrete spreader in automatic mode" explains Egor Kraus.

With industrial, weather-independent pre-production, DNS-Development will create housing for many 100,000 people in the Primorje region. Politicians are already providing targeted support for this. Currently, a state development programme has been initiated for the new Sputnik urban area in the Primorje region with 300,000 inhabitants and 2.8 million sqm of living space. At the same time, new jobs are being created, creating wealth and providing prospects for many families. "The migration to Russia's mega-cities will be stopped by this. The construction costs will not be higher, in the long run rather lower than with conventional construction", Pavel Leganov describes. Against this background, DNS-Development is sticking to its ambitious growth targets for the coming years.