The Hungarian Limelog Group transports over 300,000 tonnes of lime and gypsum, various types of grain and special concrete elements as freight every year. "Located in Dunaújváros, 60 km from Budapest on the right bank of the Danube, we are in the heart of Europe and close to our customers," says Gábor Móró, Managing Director of the international freight forwarding company. "It was the direct contact and dialogue with our customers from the construction industry that prompted us to set up our own stationary precast concrete production facility in 2011.

In Hungary, the demand for industrially prefabricated concrete elements has increased in recent years, especially in infrastructure projects, but also in social housing construction. "80% of residential buildings in Hungary are more than 20 years old. We have some catching up to do, so the construction industry is booming," reports Móró. In addition, the new construction method is faster, cheaper and more resource-saving than conventional construction with block bricks, for example. "With this in mind, we have decided to offer our customers solid concrete wall elements and staircases in the future." The investment is supported by financial means from the Capacity Development Fund of the European Union for small and medium-sized entrepreneurs.

Hydraulic stair formwork for up to 15 steps

The KOMBISTEP stair formwork 15-150 comes from Vollert's special formwork portfolio. The construction design of the staircase formwork is highly flexible. Both left- and right-rotating staircases with up to 15 steps are produced. Stair widths from 950 to 1,500 mm are possible thanks to a modular side wall. The step varies steplessly between 220 - 320 mm, the gradient between 150 - 200 mm, whereas the step hypotenuse is exactly carried out by means of a hydraulically movable scissor lift mechanism. For presetting, the steps are adjusted fully hydraulically. "We can produce very versatile stair configurations. And the conversion time, for example to adapt the stair width to the next construction project, is minimal," describes Alexander Kaspar, Project Manager Sales at Vollert. The thickness of the waist slab is variable between 100 and 200 mm. With KOMBISTEP staircase formwork, the staircase is produced overhead. This is particularly suitable for exposed concrete staircases, for staircases with edge protection or anti-slip profiles as well as for subsequent blasting or grinding. The stair formwork is provided for tilting with an integrated hydraulic function for easy shuttering and deshuttering. The step design is right-angled and therefore sharp-edged - another quality feature of prefabricated staircases. This is especially important if carpet or ceramic tiles are to be applied later.

A stair landing kit for the bottom respectively top step up to 1,500 mm can be easily installed on any step thanks to the horizontally movable and height-adjustable steel rear panel. The lateral movement of the side wall to absorb the concreting pressure is carried out hydraulically via a shearing mechanism. This makes opening and closing particularly easy and user-friendly.

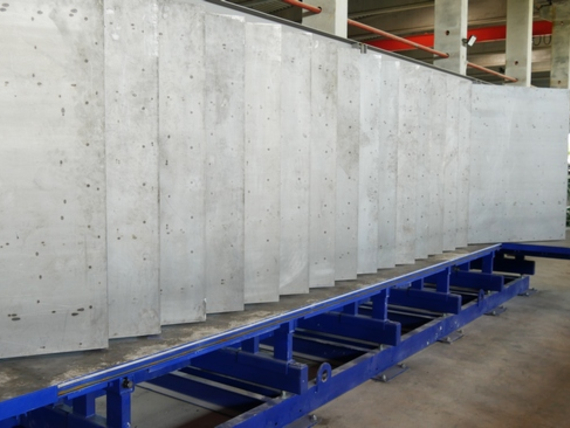

High-performance tilting tables for solid wall production

Demand for prefabricated solid walls is rising, especially in residential construction in Hungary. The new stationary high-performance tilting tables at Limelog enable the flexible, horizontal production of concrete parts up to 4 m wall width and 12 m wall height. Hydraulic tilting joints, fixed to the tilting frame and tilting trestle, set up the formwork surface up to an angle of inclination of 80° and ensure that the lifting takes place without chipping off the concrete edges. First-class fair-faced concrete surfaces are guaranteed by the flat ground formwork surface. The generously dimensioned construction ensures torsional rigidity. The lateral edge stops are freely adjustable for wall thicknesses between 100 and 300 mm. They can be folded down to the side for easy cleaning. High-frequency vibrator with group-wise vibrator frequency adjustment for homogeneous concrete compaction even with asymmetrical element allocation. Heating coils integrated in the superstructure, which work with thermal oil and water, ensure a fast curing process of the concrete.

"With the expanded production of precast concrete parts, we have significantly expanded our range of products for our customers in the construction industry," concludes Gábor Móró of Limelog. "We can also supply structural concrete elements such as columns, beams and stairs as well as solid walls for construction projects just-in-time within just a few hours".