Aleris is expanding its production in response to the increased demand for alloy metals in the automotive industries. The facility in Duffel is one of Europe's largest aluminium rolling plants and specialises in manufacturing sheets and coils made from aluminium. Since the high-bay warehouse for this facility will be the first of its kind for Aleris in Europe, the company turned to Vollert Anlagenbau, which has been providing intralogistics systems to the aluminium industry for many years. As engineers developed a customised solution, they were able to overcome different challenges: heavy loads, fast turnaround times, and automated transport of coils with and without a reel. The system also had to be designed to handle a wide range of coil diameters, which continually change throughout the milling process.

25 Tons on a Single Arm

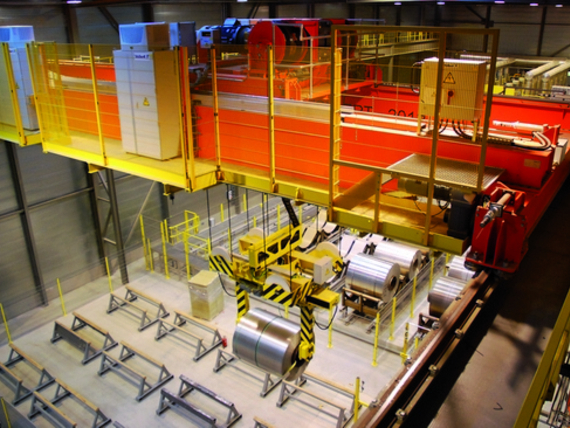

The new high-bay warehouse, which is 26 metres tall, 11 m wide and 88 metres long, functions as a temporary storage area that can accommodate up to seven coils on top of each other as they pass through the milling phases. Weighing in at up to 25 tons each, the coils are lifted and transported on the outer surface at a speed of 2.5 meters per second by a rack feeder with a single telescopic arm. "The coil diameters change continuously during milling, which is why the outer surface is the only part of a coil that remains balanced, and can therefore be used for transport, regardless of how large or small the coil is. It is also possible to handle coils with or without a reel, which makes internal transport very flexible", explains Lars Strobel, project manager at Vollert. The high-bay warehouse has direct access to a continuous annealing line with a pre-treatment facility (CALP). The coils are transfered by four coil lift trucks.

Coil manipulator ensures smooth operations

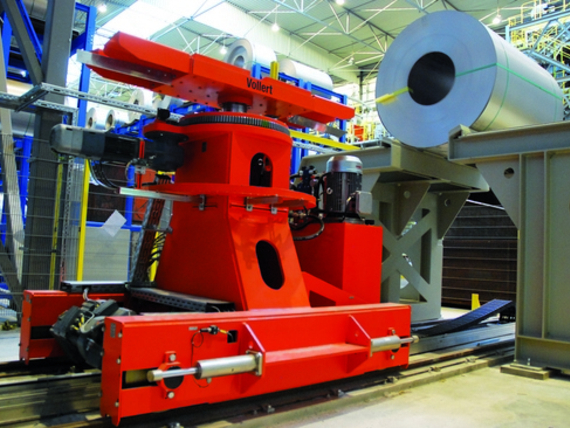

A custom-built manipulator from Vollert with slewing, hoisting, and running gear and a 19.5 meter span width unloads arriving lorries. The manipulator then performs all of the following steps automatically. Transport takes place across three axes at 1 m/s with a hoisting speed of 0.5 m/s. The gripper picks up the "eye" of the coils at the balanced centre point via an automatic measuring system and transports them to the high-bay warehouse, a separate buffer warehouse, or directly to the Sexto mill as required. The manipulator also serves an oven. After beeing treated, the hot aluminium coils (which can reach temperatures of 500 °C) return to the high-bay warehouse to cool down. All internal transport takes place fully automatically, with no manual intervention required.

The entire system was delivered to Aleris in the third quarter of 2012. The plants have been working to full productivity since the beginning of the year and the official opening of the plant took place in March 2013.