Taschkent has more than 2 million residents and is the political, cultural and economic center of Uzbekistan since the 1990s. New residential buildings are emerging just as fast as modern shopping malls, hospitals and universities. Thanks to industrialized prefabrication, construction projects are completed much faster with today's prefab architecture. Precisely dimensioned walls and floors/roofs improve the quality of construction, feature excellent thermal behavior besides being also weather and fire resistant.

"With the increase in construction activity in Uzbekistan, we came to realize this. Since 2014, we have significantly developed the construction business, while in 2016, we successfully got into industrial precast concrete production," says Aleksey Lozinskiy, responsible for production and plant engineering at DSK Binokor. For one of Uzbekistan's leading developers, the manufacture of various solid concrete parts for attractive residential buildings or multi-story car parks is a very successful business. "It took only a few months to convert the former Soviet KSK housing combine into a state-of-the-art precast concrete plant equipped with state-of-the-art plant and machine technology. Close collaboration between client and architects was very important for this endeavor," explains Igor Chukov, Vollert's Executive Sales Director CIS/Russia. Concrete plant specialist Vollert as the know-how partner and technology supplier contributed ample expert knowledge.

Earthquake-proof construction system with innovative concrete sandwich elements

DSK Binokor has again invested in another major residential project that aims at an annual production of up to 500,000 square meters of wall and slab surface based on a new building system. "This is an intelligent combination of special sandwich concrete parts, solid concrete elements for interior walls and hollow-core floor slabs. Just a few years ago, multi-story building systems were not technically feasible due to persistent seismic activities in Uskekistan, but today's architecture opens up entirely new possibilities," explains Aleksey Lozinskiy.

But also, expert knowledge in modern building systems contributed by the Vollert engineers was very crucial. Way back in 2015, Vollert, together with the construction company BauMax and the earthquake specialist Sirve SA, developed a special construction system for earthquake-prone Chile. Vollert applied this know-how to the specific seismic conditions of Uzbekistan. A novel viable building system was developed for high-rise residential buildings. Specially designed sandwich walls are the most important feature in terms of load-bearing capacity, even more so when it comes to strong earthquakes. They feature reinforced concrete frame connections and caissons to absorb the forces. For this purpose, DSK Binokor has developed a special wall construction in close cooperation with the Vollert construction engineers. "Besides solid walls, which we are producing since 2016, we decided to also invest in a new sandwich wall production line," said Saburov Bachtiyor, CEO of DSK Binokor.

A plant design with many sophisticated features

"The second production line was built in less than 10 months," tells Igor Chukov. The sandwich wall consists of a flat concrete slab, the insulation layer as well as a massive concrete upper shell with the necessary reinforcement connections. A special shuttering system, developed in Russia, enables the construction of the sandwich wall layer by layer. Colored concrete can be used during the casting process for certain types of concrete walls. "We had to take this into account already during the preliminary planning stage of the plant design," Chukov explains.

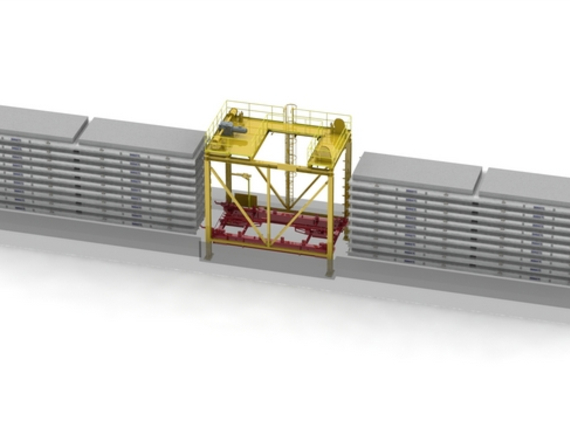

Machine technology as well as the transport and loading areas were specifically designed for DSK Binokor. By means of an industrial plotter, the CAD/CAM-controlled SMART PLOT, wall contours are applied, shuttering profiles positioned and the reinforcement mesh for the lower shell inserted. A state-of-the-art CAD/CAM-controlled SMART CAST concrete distributor applies the exact amount of concrete defined for the flat concrete slab with a spiked roller / slide construction while hydraulically actuated flat slides make sure that sections like window spaces, where no concrete is needed, are left without. The Vario COMPACT vibration station ensures optimum concrete compaction and exposed concrete of high quality on the underside. After a short setting process, the insulating panel is placed on top and additional reinforcing mesh for the massive top shell is inserted. The concrete is placed and compacted via a high-frequency shaking station. The SMART CAST concrete distributor travels between the concrete placing positions by means of a special bridge system. By separating the different concreting areas, we have optimized the flow ensuring a high cycle while avoiding standing times.

Attention was paid to time-saving work flows also in the subsequent curing process. The sandwich wall travels through an insulated intermediate hardening tunnel right after the second concrete placing process. Thus, the top shell achieves the right binding strength for the smoothing process that follows next. An electrical smoothing machine, the Vario SMOOTH, with wing adjustment and adjustable speeds of rotation moves in longitudinal and transverse directions to ensure a surface smooth as the shuttering. The other technical highlight: the fully insulated Vario CURE curing chamber with two tower systems set in series. These two towers have 9 shelves each to accommodate pallets. This tandem design is a particularly innovative, space-saving concept, as two circulating pallets can be stored on the same shelf compartment. The shelving towers are heated and each one has a pass through/ exit level with sectional lifting doors that make sure that no heat is lost. The floor-mounted Vario STORE, a storage and retrieval machine, is installed midway between the two rack towers. Storage and retrieval happens fully automatic. By means of a special coupling system, the circulating pallets are transported in pairs through the shelving towers. Also the warehouse and production processes are centrally controlled via the VCC control system (Vollert Control Center), which creates the order dispatch list, optimizes pallet allocations, determines the storage and retrieval sequences, and manages curing times and loading processes. Statistical evaluations of the plant's efficiency are available at any time. Printouts of labels, pallet occupation plans or reports make the production process transparent and the subsequent storage bin management easy.

First earthquake safety tests successfully passed

The new construction system was tested on earthquake stability in October 2018. For this purpose, the shell of a 9-storey residential building was exposed to a magnitude 9 earthquake. The KazNIISA Institute of Seismology used a special vibration exciter to generate vibrations that are similar to those of a real earthquake. "The sample building serves as a model for a major construction project in the heart of Tashkent. The tests ran smoothly, the building system stood the test and we are expecting a large order for this type of house in the near future," explains Saburov Bachtiyor. "Concerns on the part of the public opinion and politics were cleared very quickly."

Novel hollow-core slab production planned for 2019

As for 2019, DSK Binokor is investing in a third line and expanding its current hollow-core slab production. "This is a necessity in order to achieve the expected capacity of future construction projects. And we are going to break the mold. We will implement a new manufacturing process for prestressed hollow-core slabs that is new across the world. We indeed see ourselves as a real pioneer," says DSK Binokor Aleksey Lozinskiy. Up to now, prestressed hollow-core slabs are produced incessantly by extrusion or slip forming methods. After curing, the slab elements are cut to size appropriate for the site, which is very cost-intensive. Embedding additional reinforcements or a lateral reinforcement in cement for friction connection of the slabs in earthquake-prone areas is almost impossible or comes at great expense. Vollert's innovation takes an entirely different approach. The hollow-core floor slabs are produced using the pallet circulation principle instead of the production principle in lines. A greater slab width results in fewer heavy crane lifting operations, and shortens the installation time on the construction site. Higher load-bearing capacity and frictional connection of the floor slab elements for earthquake-proof building systems is achieved by additional reinforcing steel meshes and reinforcements. Shafts for electrical lines, water or ventilation pipes or other special built-in parts can be incorporated. As a result, structural engineers or TGA planners have a range of utterly new possibilities compared to the previously known prestressed hollow-core slabs.

We are going to sustainably change the construction industry in Uzbekistan with this new prefabricated building system," says Aleksey Lozinskiy. "We can finally meet the high demand for low-cost residential buildings that also features high-quality and is earthquake-resistant at the same time. And all this comes with a totally new architecture." Up to 12-story building systems are currently in the planning phase. "We do not see ourselves merely as a plant supplier, but as a real long-term engineering and know-how partner for our clients," adds Igor Chukov from Vollert.