“Many building material manufacturers are developing their concrete block range to always keep up with current trends, combining economic and ecological aspects today. At the same time, customers are imposing ever greater demands regarding surface quality and beautiful shapes,” explains Alexander Kaspar, project manager sales at Vollert. Such a range of building materials can only be produced with cutting-edge formwork technology today. In light of this, formwork specialist Vollert has developed new solutions for L- and corner element production alike.

Hydraulic duplex formwork system for L-blocks

L-blocks are support elements for gardening and landscaping, used as edging for beds, to stabilise slopes, as walls, or to build boundaries. “Such L-blocks in particular have often been made in horizontal individual production or small production batches so far. These are very time-intensive while driving up the sales price for each single block,” Alexander Kaspar tells us. “We now offer multifunctional duplex formwork systems to produce high-quality L‑bricks in a wide range of dimensions.”

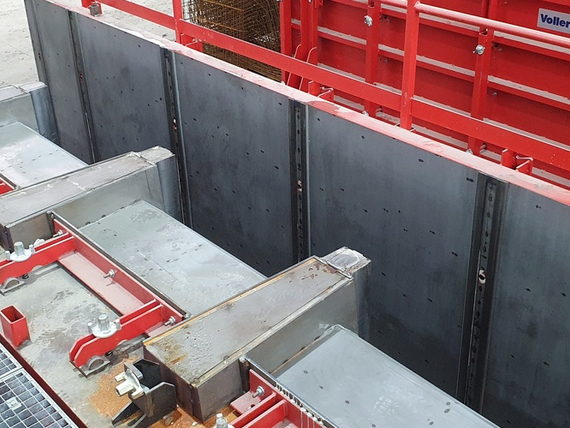

Brick formwork systems can produce various element sizes. For example, up to 10 L-blocks with wall thicknesses of 12 cm can be produced simultaneously on a single duplex mould. Block sizes of 55/30 cm or 80/45 cm, 105/60 cm or 130/70 cm, and 180/100 cm or 155/85 cm are available. “The L can be formed in two brick heights to maximise flexibility. The bottom shutter can be moved or adjusted up and down,” Alexander Kaspar explains.

Upside-down production for high exposed-concrete quality

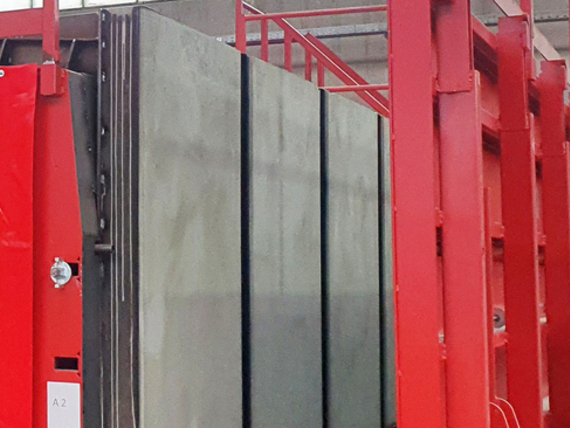

The bricks are produced upside down, which has the advantage of having the visible sides resting on the shutter surfaces to ensure outstanding surface quality. Each duplex formwork system can produce 8 L-elements with block widths of 99 cm as well as 2 L-elements with block widths of 49 cm each. The visible sides of the brick are the ascending faces on either side. The side to be manually smoothed is the base bottom. The lateral longitudinal shutters of the outer walls are made in a single piece, manually locked and unlocked with quick-release screws for the concreting process. The longitudinal shutters of the external walls can also be optionally designed with a hydraulic locking mechanism. The side shutter is folded down or moved hydraulically. The bottom shutter is adjustably attached to the base frame, with a circumferential 10 x 45° steel bevel on the visible sides. The interim stops are divided due to the chamfer geometry, i.e., one part is fixed to the steel core, while the other will move along with the lateral wall for demoulding. Optionally mountable spacers also enable production of additional smaller brick widths.

“We often use self-compacting concrete for this, as it eliminates the need for cost-intensive vibratory equipment or manual re-compaction of the concrete,” Alexander Kaspar adds. Heating registers that can be integrated as options ensure uniform heat distribution for significantly shorter curing, and therefore demoulding, times. Every duplex mould has a walk-on bar that is accessible from the front for a high level of working safety and to prevent accidents. Guardrails installed on the two movable side shutters and the two front faces serve as fall protection.

Efficient and safe lifting and loading processes

Vollert has additionally expanded its new formwork portfolio to include corner element shutters for all suitable block sizes to offer a complete construction kit. “We recently installed free-standing L- and single-corner shutters for single-piece corner elements with side lengths of 49 cm for a customer in Germany,” explains Alexander Kaspar. “The basic setup comprised fire plates with L-shaped shutter sheets on either side arranged at an angle, with a 10 x 45° steel chamfer on the long sides.” The L-shaped side shutter is moved diagonally with a pneumatic system to enable safe demoulding. Water-controlled heating coils further ensure optimal and rapid curing.

Crane-guided vacuum lifting beams offer an interesting option to lift both the L-bricks and the corner elements safely and particularly ergonomically from the mould after demoulding. Adjustable vacuum plates attach to the angular elements, which may weigh up to 1,000 kg, lift them up, and turn them by 90° using an electric motor-powered turning mechanism in order to position them for subsequent packaging and loading.