With a total of three locations, the Soriba Group specializes in the production of architecturally high-quality and attractive precast concrete elements. In addition to facade elements and walls, this also includes different variants of precast concrete staircases, also of the highest premium quality. Until now, the innovative building materials manufacturer has used purely conventional, stationary manufacturing processes based on stair formwork at the Fontenay-le-Comte site near the French Atlantic coast. However, the objective of Managing Director Stéphane Garnier was to streamline and optimize this time-consuming and labor-intensive manufacturing process - and thus to entirely rethink it. In the German precast concrete plant specialist Vollert from Weinsberg, he found the right partner for this purpose, as Philippe Marrié, Project Manager Sales at Vollert reports: "With this new plant concept, all production-side processes were really reviewed and optimized right from the start - from the shuttering process, through the concreting and curing process, to the automated and weight-optimized truck loading sequence. And in the end, many new ideas and improvements were optimally implemented. The result sets completely new standards and is also something special for us as an experienced manufacturer of precast concrete plants. " Soriba laid the foundation by using special edge formwork pallets - these are essential for rationalized production of the different types of stairs, depending on the building project. The plant experts from Vollert contributed the necessary know-how in the areas of automation and innovative machine technology, resulting in a new plant concept in Industry 4.0 standard, which not only saves time and money, but also reduces the CO2 footprint due to considerable material savings and the use of renewable energies.

Concrete stairs by the minute

Variable edge formwork pallets form the basis for the circulation-based manufacturing process, because precast staircases are designed very individually depending on the client's requirements and vary from building to building. The treads and step heights are standardized. "In advance, we defined several formwork pallets as standard for this purpose, which are now available for selection on the production side and allow individual stair widths in centimeter increments. A high-quality steel covering guarantees the high surface quality of the stairs," says Valentin Garnier, project manager at Soriba. In the actual circulation process, the procedure then resembles the work steps of a proven precast concrete production. After the shuttering process, the reinforcement is placed, followed by the concreting process, curing and subsequent smoothing, as well as turning and stripping the precast concrete parts out of the formwork mold. "Compared to stationary formwork systems, this new manufacturing process significantly reduces the time required, so that larger quantities can be produced in a shorter time.

Sticking point is the turning process

But the Vollert engineers did not simply settle for the usual process. With a view to resource-saving and sustainable production, all options to save raw materials, energy and CO2 were examined. The experts at Vollert surprised everyone by suggesting that the turning process of the concrete stairs should also be automated and designed to be gentle on the product - because this provides the basis for massive material savings, as Philippe Marrié explains: "The turning and rotating of the finished concrete elements is the crux of stair production - in the truest sense of the word, because this is where the highest loads and bending requirements are placed on the concrete structure. In later use, these high stability criteria are no longer needed. If we design the turning and rotating process to be gentle on the product, we can save significant amounts of reinforcing steel and concrete. " Vollert developed a special turning device that locks and turns the entire formwork pallet including the concrete element after automated removal of the movable edge formwork. This gentle and relieving process allows a significant reduction of reinforcement in the concrete element. In addition, turning and demolding are carried out simultaneously in just one work step.

Less concrete, less steel, less CO2

In addition to the reduced reinforcement, the optimized product-friendly turning process also reduces the cement content and thus the largest CO2 source in precast concrete production. This is further enhanced by an energy-optimized curing process, according to Marrié: "The curing process is fully automated in two steps within the curing chamber. This is divided into two heat zones and offers extensive storage space with the rack towers. In the first zone, the curing process is started by pulse heating. Afterwards, the pallet is moved by the rack operator to a lower temperature range, which, however, is completely sufficient for the further hardening process, because we use the energy of the exothermic concreting process in the staircase as well. As a result, the dwell time of the pallets in the curing chamber is slightly longer, but the cement requirement is reduced - in fact, significantly.“ Soriba also achieves an additional cement reduction during concreting and compaction by using a shaking station with patented Vollert pendulum suspension. The resistance-free shaking process ensures optimum energy input into the concrete, resulting in further cement savings. "In addition to lower costs, the cement reduction leads to a significant reduction in the CO2 footprint in precast concrete production, as cement production is the largest contributor to this," emphasizes Philippe Marrié. As an energy source for the curing chamber and for the overall production, Soriba uses geothermal and solar systems and, of course, appropriate thermal insulation of the Vollert curing chamber is also mandatory.

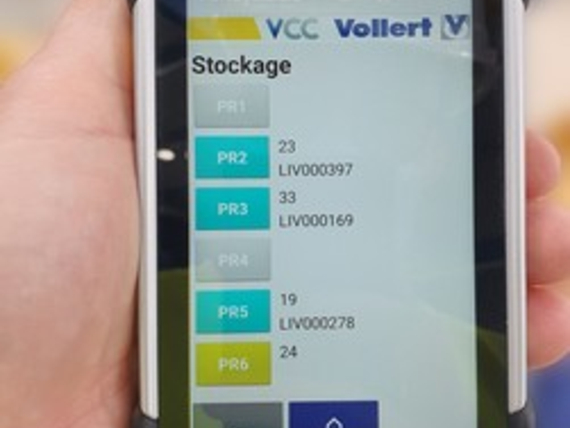

Mobile control 4.0 - interactive and paperless

For the control software, Soriba also relies on state-of-the-art solutions and continuous data tracking for each concrete element. Data control is carried out in Industrie 4.0 standard via the Vollert Control Center (VCC). Interactive QR codes link it to each stair element and thus enable continuous work control, documentation and quality control. After a scan, mobile devices display the work steps that have already been carried out and the next ones - and also pass this information on to the next employee for each stair element. In this way, all those involved always receive direct information about the upcoming processing or transport tasks - completely paperless. A database ensures the connection of the Vollert master computer to the Soriba ERP system.

Fully automated up to truck loading

"The control of the individual manufacturing processes does not end with the finished cured stair element, but also includes the correct intermediate storage and delivery sequence for truck transport," says Philippe Marrié. "For example, when the finished workpieces are accepted, the correct sequence for storage is specified in order to achieve optimum utilization of the trucks during subsequent retrieval and loading." The goal of the automation is to keep the number of movements of the stair elements as low as possible. "For example, we only need two crane movements to put the stairs into storage, which is significantly less than in a stationary production facility." After turning and stripping, the control system assigns each staircase one of six waiting positions in three safety areas. These serve as buffer positions to be able to achieve the high speed in circulation. A transfer car then automatically transports the concrete element on transport racks to the open-air site and makes them available, optimally prefabricated, also on call for the loading process. And Soriba's new production line also goes one step further in terms of ergonomics: In order to achieve an optimum processing height of the circulating pallets for the employees, Vollert developed a special low-floor system with friction wheels recessed into the floor for the feed. During transverse movement, the pallets are then raised extra so that the transverse lift trucks can drive under the pallets.

Soriba Managing Director Stéphane Garnier is satisfied with the result: "With this completely new staircase production - the first in the world using the circulation process - we have really succeeded in doing something unique so far. Automation significantly reduces the handling effort, saves time and is both sustainable and ergonomic. We reduce the use of raw materials such as formwork wood, reinforcing steel and fossil energy, and make significant savings on concrete thanks to optimum compaction in the shaking station, the low-load turning process and the optimized curing process. All this leads to a considerable reduction in CO2. And at the same time, we manufacture high-quality concrete stairs in high cycle rates."